“Everything is a learning process: any time you fall over, it’s just teaching you to stand up the next time.” – Joel Edgerton

Understanding and embracing this learning process is the ultimate key to success. Success is in fact at the end of a very long and twisted road that is loaded with challenges. And with every hurdle you face, lies an opportunity to truly push yourself beyond your limit to learn and grow.

In this article, you will learn from real-life examples of giant companies like Huawei, BMW, and John Deere who are truly exceptional in their respective fields. But had to truly struggle and had to endure enormous challenges in their organizations to get to where they are now.

These issues majorly ranged from having no clarity on agile methodologies, incomplete team structures, and scaling difficulties. For solving these problems, these companies implemented Large Scale Scrum (LeSS) that not only transformed their way of working but brought a shift to the mindsets of the people working.

Huawei

Huawei Technologies Co. is a Chinese multinational company that specializes in telecommunications and network equipment, consumer electronics and services. It is based in Shenzhen, Guangdong, South China. According to IDC, Huawei has become the second largest smartphone maker behind Samsung. It has also become the world’s seventh-largest information technology company by revenue. But achieving this status took them a lot of time and a broad reconstruction of their organizational structure. It wasn’t until 2016 that they embraced the agile culture purely and adopted one of its most recognizable frameworks, LeSS.

Before transitioning to the LeSS framework, Huawei was working in a traditional management style with project managers and at the same time struggling with trying an agile adoption. The problem was that they were unclear of their agile methodologies and weak team structure. This lead to issues that are described below in the list:

- They tried working in iterations which eventually turned out to be mini waterfalls.

- There was continuous integration where the developers thought that they integrated their code together but in reality, they were just confusing it with daily build and automation.

- Cross-functional teams were made. Essentially these teams are meant to be self-managing and self-organizing. But there was no guidance on how self-management was to be done. Instead, there was still a manager that would manage to achieve the goal for their teams. The team was just a mix of people in an unstable team structure with an unclear vision and weak alignment. These individuals were just focused on their respective specialties that resulted in reduced learning and adaptability and not taking a shared responsibility.

- Scrum was tried but since the organization and the team structure weren’t well defined, it did not work.

- The product definition was not clearly done.

- The work was scattered as there was no single backlog managed by multiple managers

- Traditional program management was done instead of product management

Huawei was in dire need of guidance and restructuring. In 2015, agile coaches were hired to give proper guidance and awareness about agile to the teams.

An organization-first approach was done. This top-down adoption was done because a proper organizational structure was needed first, which will eventually pave the way for effective coaching that will solidify the concepts of LeSS.

The transition started from first defining an organizational and team structure. It was a daunting task as it challenged the power and authority of the management. Even scrum masters were baffled with the idea of having teams that were self-managing without having an appointed manager. This had to be changed.

The coaching for LeSS was done in an evolutionary-increment approach. Work was arranged in programs, rather it should be organized to be product-centric. Instead of just rolling out the product, the approach in LeSS dictates that product development should fulfill exactly what the customer wants. There was also a focus on improving product definition.

After a year of coaching, the concept of having a single backlog was introduced with one product owner, rather than having multiple managers with multiple backlogs. The traditional phases of development such as analysis, building and testing were replaced with one common definition of done for all requirements. All of this greatly helped Huawei escalate into the tech giant that it is today.

BMW

Bayerische Motoren Werke or Bavarian Motor Works (BMW) is a German multinational company that manufactures luxury automobiles and motorcycles. Started in 1915, it manufactured aircraft engines till 1945. And after that, it shifted to producing cars and motorbikes. It has been ranked number 1 as Best German Business Brands International by Das Deutsche Markenranking in 2017 and ranked number 10 on Forbes’ World’s Best Employers List 2018.

LeSS was implemented in 2012 during the BMW iCar Project when a new Unified Sales Platform (USP) was needed to support its development. This USP had to be integrated with 30 external system interfaces that were non-agile. So to ensure uniformity and coordination across all platforms, LeSS posed an ideal solution.

The challenges BMW faced before adopting LeSS were:

- Product definition was murky

- Employees were not familiar with agile methodologies

- Teams were not self-managing or cross-functional

- Unclear on the definition of done

- No single product backlog

Considering these issues, a bottom-up approach was taken. Instead of having an organization-first approach like Huawei, the BMW group went with the scrum-first approach. Scrum was applied to one team. This team explored and discovered all the tools needed to set up the development environment, a system for continuous integration, and defining the length of the sprints. The progress with this team showed a significant difference in performance as compared to the other teams.

The other teams were still set within their traditional management style. Since requirements and priorities could change, there was still a need for a much more flexible working environment. Instead of being limited to doing one task, teams should possess the freedom to select various items from the Product Backlog to make end-to-end features.

There were multiple teams in the company, consisting of hundreds of employees. This urged a need for uniformity of the processes to be followed and coordinated across all of them. Since scrum was successful with one team, the idea was to spread it to all the teams and apply it entirely.

For transforming to LeSS, agile coaches were hired that dispensed guidance through constructive and interactive coaching workshop sessions.

These workshops would last for hours which were focused on advising and educating the employees on how LeSS works. Team building sessions were held in which team members were trained on how to share knowledge, discover impediments and ways to improve with each other.

Team vision charters were a critical part of the coaching session. Guidance was given on how to stay committed to a vision and focused on a common goal. The essence of product-centric development was taught.

These workshops led the way for creating self-managing and self-organizing feature teams. And after two years, in 2014, productivity remarkably increased. As the work became more transparent and with features properly prioritized, decision making was greatly enhanced. This also increased product predictability and reliability.

John Deere

Recognized for the manufacture of its construction and agricultural machinery and being in existence for over 150 years, John Deere has been ranked as one of the Best Global Brands by Interbrand in 2018.

Similar to the weak organizational structure of Huawei, John Deere was in serious need of a transformation. Their problems were mostly related with:

- Feeble team structure

- Inability to predict product delivery

- Problems with maintaining quality

- Multiple product owners

The transformation started by first educating the managers to become better lean leaders. During this process, there was help from senior developers and a session with Craig Larman, the co-founder of LeSS, who gave guidance on the framework. His guidance was valuable as he greatly emphasized rebuilding the teams into being self-managing and self-organizing. Through team-building exercises and workshops, team members were trained on being cooperative and collaborative with each other in a team.

After six months, progress at John Deere improved considerably. The concept of having a single product owner and a backlog was introduced. With the product backlog being a single entity and the team structures being properly set, the quality and reliability of the production boosted. The essence of learning and adapting and continuously improving brought a whiff of freshness to the working environment.

“The beautiful thing about learning is nobody can take it away from you.” – B.B King

Conclusion

Making a transformation takes time, proper guidance, and patience.

Agile is centered at the roots of an organization. No matter how big or small, the foundation for agile should be strong to support its methodologies. So having clarity on how everything is meant to behave and work in agile is extremely important.

Agile coaches play a mammoth role in bringing about a change. The experiences shared by agile coaches are an excellent source for the employees to learn and relate from. Their services can be easily tailored around an enterprise to suit the company’s requirements. They help unlock the true potential of a company to attain peak performance.

And lastly, coupled with steadfastness and perseverance, the entire process of a company’s transition can be made smooth.

If you’re interested in having a comparative review of different scaling agile frameworks, click here.

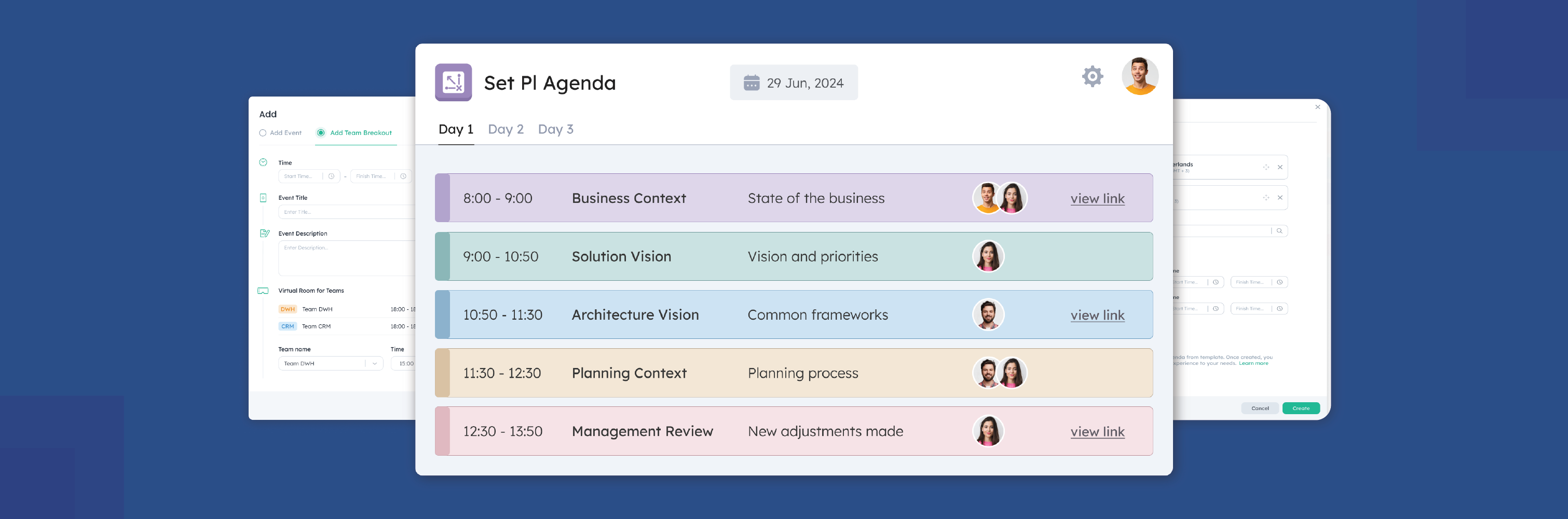

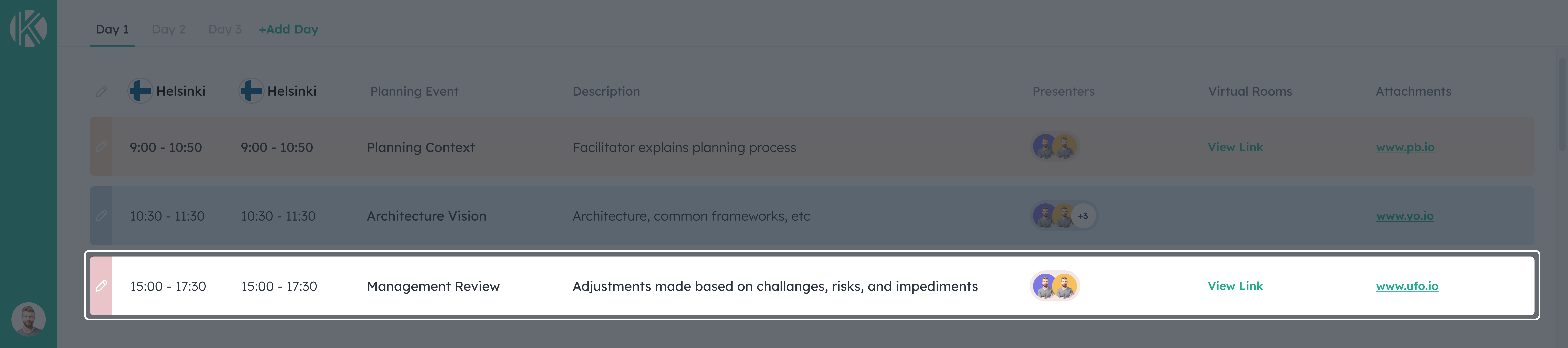

About Kendis

Digital boards to manage dependencies, multiple teams and program increments for scaling agile initiatives.

Kendis works on top of JIRA and other agile tools, your teams can keep on working with their existing JIRA boards and program level and above is planned and managed at Kendis.

Try out 10 days free trial or book a demo with our product expert.